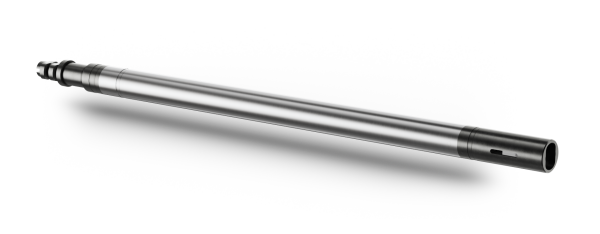

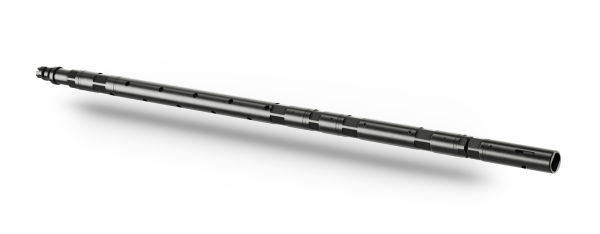

The LiMAR Multi Roller Tungsten Stem provides the necessary mass and reduced friction required for a wireline toolstring to overcome deviation and the upward-acting effects of well pressure.

This is achieved by integrating the LiMAR® Multi Roller Wheel Subs above & below a tungsten-fifilled housing section. Tungsten provides additional mass per equivalent volume compared to standard stem made from conventional steel. Strategically placed along the length of the wireline toolstring, the mass and drag reducing properties of the LiMAR® Multi Roller Tungsten Stem also serves to enhance bi-directional impact forces during jarring operations.

TOOL APPLICATIONS:

- To reduce toolstring friction and provide the necessary mass required for a wireline toolstring to reach and function at depth

DESIGN FEATURES & BENEFITS:

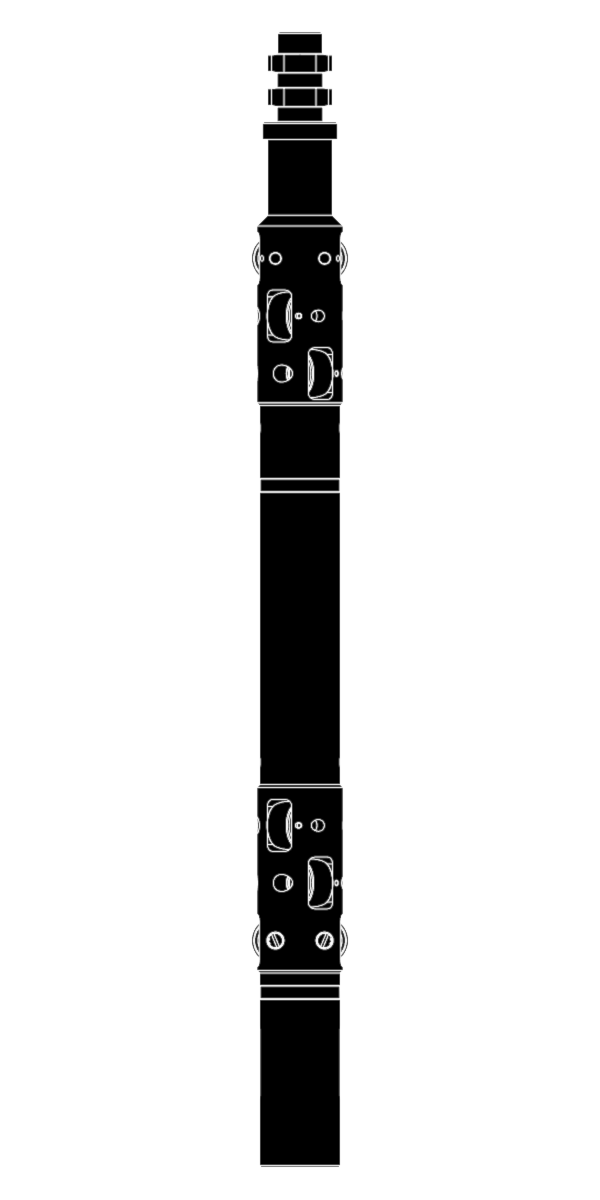

- Short, compact design of LiMAR® Multi Roller Wheel Sub

- Available in a range of sizes to suit all completion designs

- Hardened axles and wheels with replaceable bushings

- Integral grease nipple for ease of maintenance and operation

- Connection options to suit customer requirements

- Selected components QPQ treated

- Hexagonal flats for safe make-up & break-out

TECHNICAL DATA

| Assembly Part No. | Body OD | Effective Roller OD | Fish Neck | Connection | Length Options |

| 1134-1250-XX-XXX-RX | 1.250" | 1.480" | 1.187" | Optional | 2' / 3' / 5' |

| 1134-1500-XX-XXX-RX | 1.500" | 1.750" | 1.375" | Optional | 2' / 3' / 5' |

| 1134-1875-XX-XXX-RX | 1.875" | 2.250" | 1.750" | Optional | 2' / 3' / 5' |

| 1134-2125-XX-XXX-RX | 2.125" | 2.375" | 1.750" | Optional | 2' / 3' / 5' |

| 1134-2500-XX-XXX-RX | 2.500" | 3.250" | 2.313" | Optional | 2' / 3' / 5' |

XX - Denotes stroke length

XXX - Last 3 digits of part number denotes connection type

For additional sizes or further information please contact sales