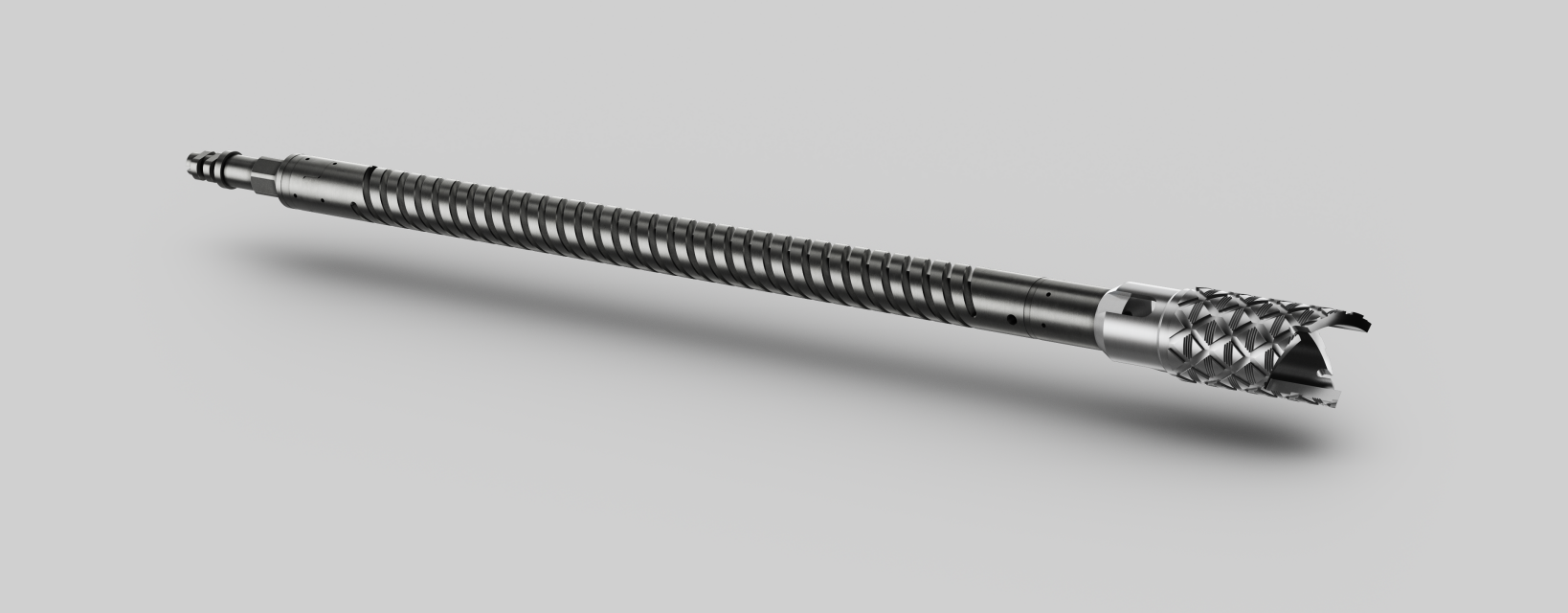

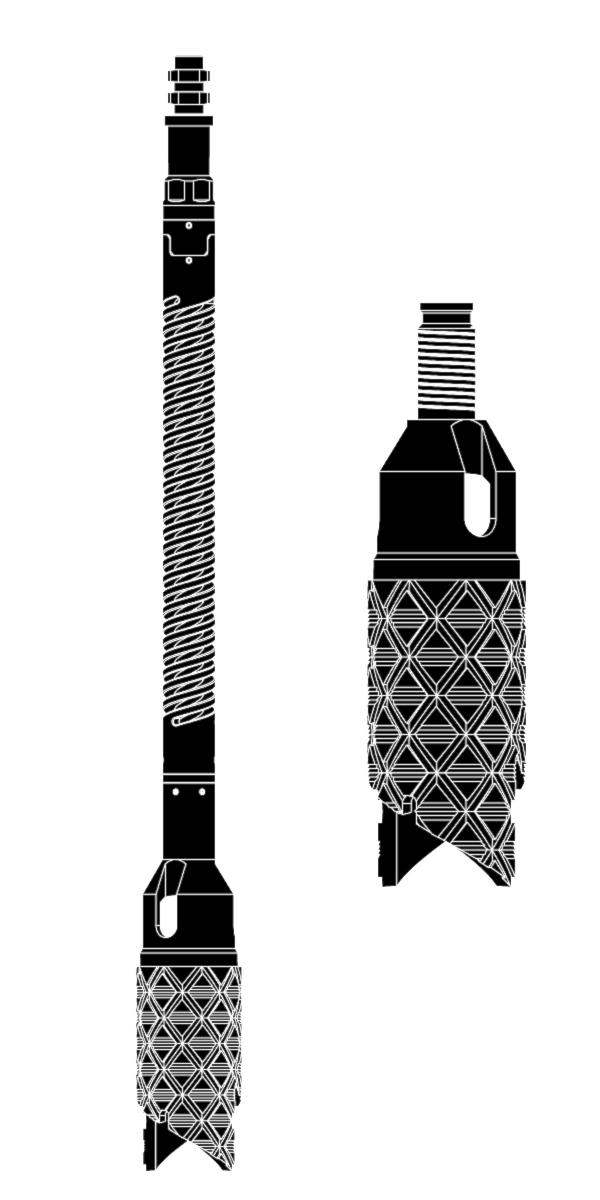

The LiMAR Rotary Broach System is designed to clear stubborn tubing restrictions such as hard scale and sand deposits in the well bore.

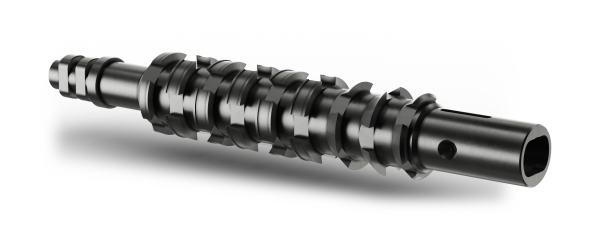

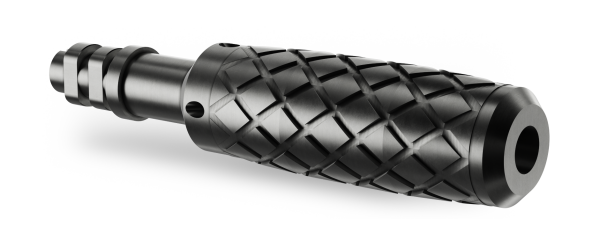

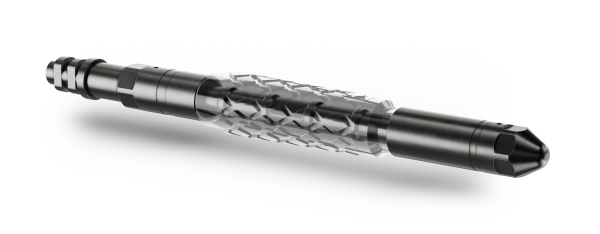

During downward jarring, the momentary torque-action, driven from the helical milled slots, attacks the restriction directly and radially, helping break up of tough deposits. Formulated around a common Rotary Mandrel, the Broach Shoe sizes can be supplied specifically to suit customer requirements.

TOOL APPLICATIONS:

- To remove tubing restrictions caused by scale or debris build up on the tubing wall or nipple profile

- The torque-action provides an additional radial motion to assist in the breaking up of tough deposits

DESIGN FEATURES & BENEFITS:

- Rotary Mandrel supplied in common tool diameters; 1-1/2”, 1-7/8”, 2-1/2”

- Lower interchangeable Broach Shoes available in a range of sizes to suit all completion designs

- 360deg cutting face ensuring full coverage during broaching

- QPQ hardening for improved performance and longevity

- Through-bore bypass reducing “cushioning” effect and weight

- Connection options to suit customer requirements

- Selected components QPQ treated

- Hexagonal flats for safe make-up & break-out

TECHNICAL DATA

| Assembly Part No. | Mandrel OD | To Suit Broach Shoe Sizes Up To (Ordered separately) | Fish Neck | Connection |

| 1228-1500-XXX-RX | 1.500" | 3.000" | Optional | Optional |

| 1228-1875-XXX-RX | 1.875" | 4.000" | Optional | Optional |

| 1228-2500-XXX-RX | 2.500" | 6.000" | Optional | Optional |

XXX - Last 3 digits of part number denotes connection type

For additional sizes or further information please contact sales