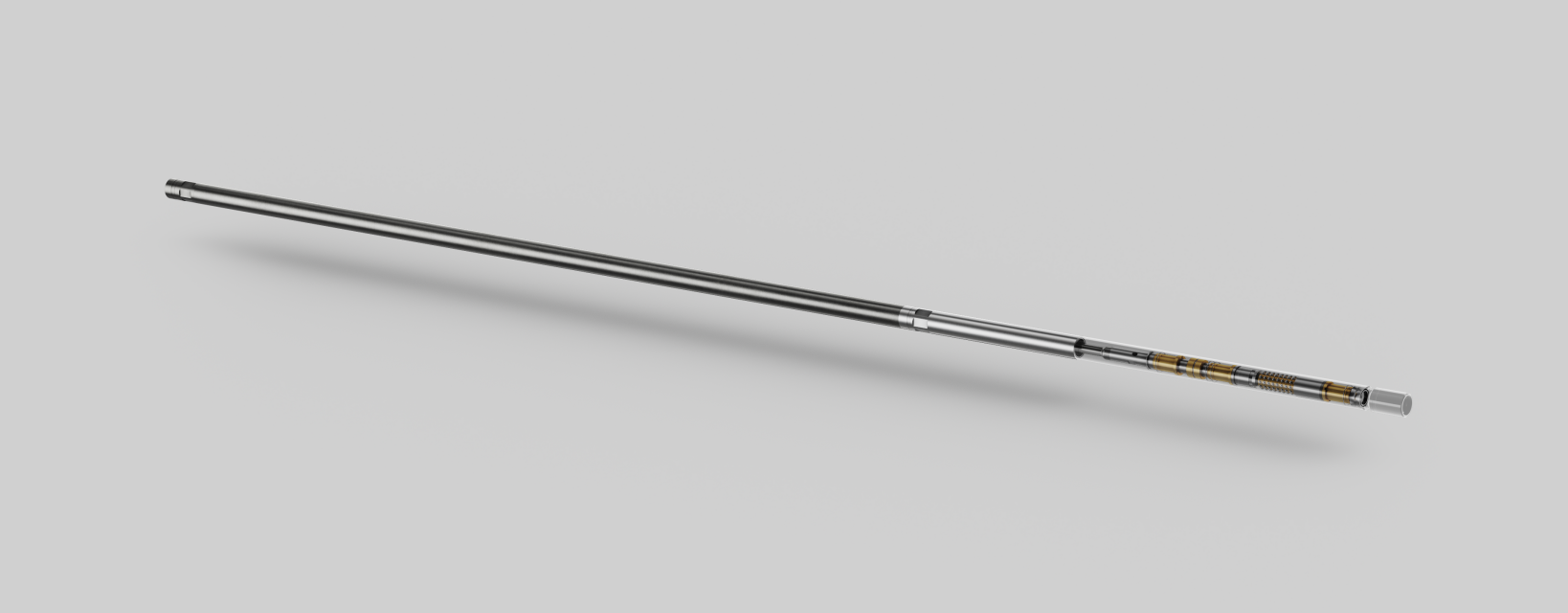

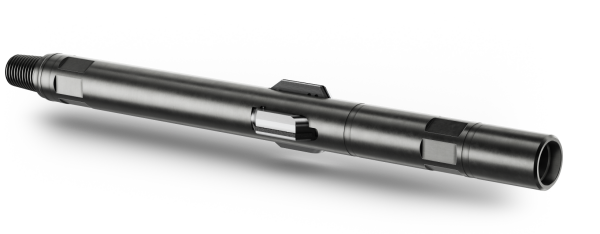

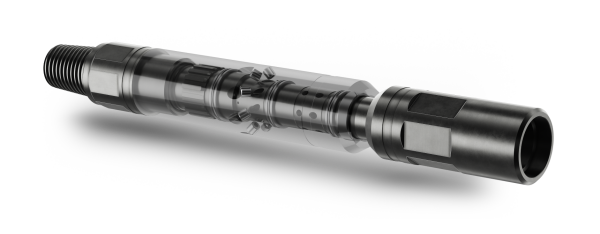

The LiMAR PDM features a low friction oil lubricated bearing assembly to limit wear of internal components and provide maximum life expectancy.

The PDM is offered with a range of power sections to suit every application, whether it be high temperature environments, a high torque requirement, nitrogen applications or acidizing operations, there’s a solution to suit every eventuality.

TOOL APPLICATIONS:

- All Coiled Tubing milling & drilling operations, under balanced applications, under reaming & challenging cleanouts

DESIGN FEATURES & BENEFITS:

- Low friction bearing section, reduces power losses and maximises lifespan

- High quality fully synthetic oil further improves operating life

- Compression and tension overload protection to avoid damaging bearings

- Titanium flex shaft further improves reliability and running hours

- Chrome and tungsten carbide coated rotors available

- Power sections available to cover all applications

- Rotor catch included as standard

- Available in a range of sizes to suit all industry standard Coiled Tubing BHA’s

- Selected components QPQ treated

- Connection options to suit customer requirements

- Corrosion resistant materials

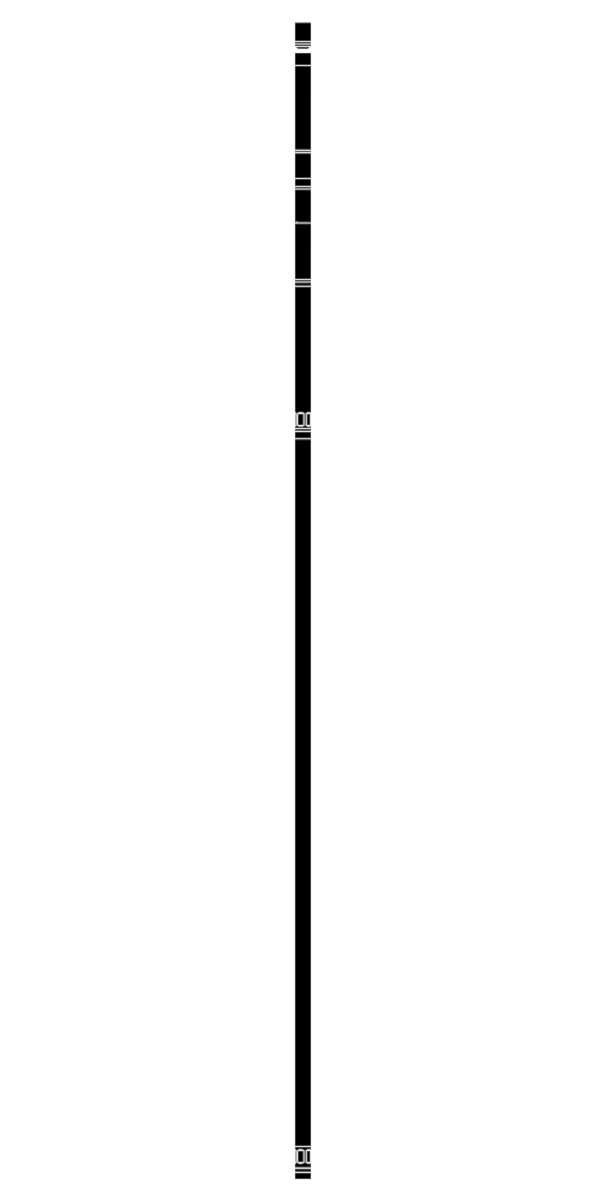

TECHNICAL DATA

| Assembly Part No. | Actual OD | Standard PDM Length |

| 278-1687-565-NXCR-XXX-R0 | 1.687" | 146.12" |

| 278-2125-566-NXCR-XXX-R0 | 2.125" | 143.65" |

| 278-2875-5647-NXCR-XXX-R0 | 2.875" | 159.90" |

| 278-3125-7825-NXCR-XXX-R0 | 3.125" | 154.15" |

XXX - Last 3 digits of part number denotes connection type

For additional sizes, screen insert slot sizes or further information please contact sales