OVERCOMING WELLBORE CHALLENGES WITH THE LiMAR HELICAL DRIVER

28th April 2025

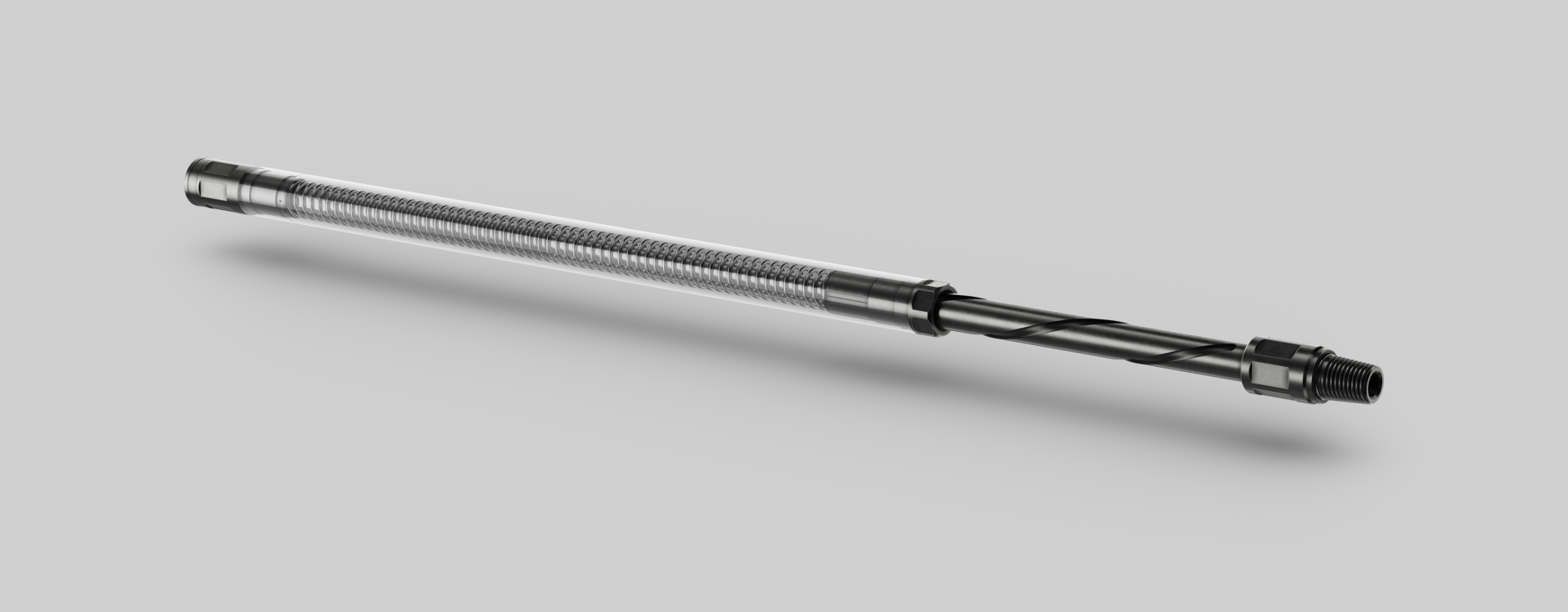

LiMAR® continues to set the standard for coiled tubing innovation with the introduction of the LiMAR® Helical Driver— a specialised solution designed to combat the toughest wellbore restrictions and open-hole ledges during coiled tubing operations.

Purpose-Built for Precision and Power

The LiMAR® Helical Driver is engineered to provide controlled rotation of the Bottom Hole Assembly (BHA) in highly challenging environments. By applying set-down weight, the tool’s helically machined mandrel drives the lower section to rotate, delivering crucial force to advance the BHA past obstructions. When the set-down force is reduced, the tool resets, ready to rotate again as needed.

This simple yet robust mechanism allows operators to persist through debris, tight spots, and irregularities without needing to withdraw and reconfigure equipment — saving time, reducing risk, and improving operational success.

Key Features of the LiMAR® Helical Driver

- Controlled BHA Rotation: The helically machined mandrel translates set-down weight into precise rotational movement, helping navigate difficult restrictions.

- Flo-Thru Design: Maintains full bore flow capability, allowing other coiled tubing BHA components to operate seamlessly below the driver.

- Fishing Capability: Designed to optimise tensile load transfer for effective fishing operations.

- Compact Assembly: Minimalistic design allows for fast redress and rig-up, supporting rapid deployment in the field.

- Robust Materials: Manufactured from high-grade, corrosion-resistant alloys with QPQ-treated components for enhanced strength and longevity.

- Simple Handling: Hexagonal flats are integrated for safe and efficient make-up and break-out at the surface.

- Drop Ball Compatibility: The tool features a thru-bore design suitable for use with drop ball release subs and assembly tools.

Applications of LiMAR® Helical Driver

- Advancing BHAs past wellbore restrictions

- Negotiating open-hole ledges

- Fishing operations in challenging conditions

- Situations requiring repeated rotational force without pulling out of hole

- In operations where the toolstring is likely to encounter stuck or immobile objects, the LiMAR® Helical Driver can be paired with the LiMAR® Torque Limiter. This setup protects the toolstring from excessive torque build-up, ensuring safe and controlled intervention.

TECHNICAL DATA

| Assembly Part No. | Actual OD | Make-Up Length |

| 252-1689-XXX-R0 | 1.689" | 50.1" |

| 252-2125-XXX-R0 | 2.125" | 54.7" |

| 252-2875-XXX-R0 | 2.875" | 60.3" |

(Note: 'XXX' denotes connection type. Refer to LiMAR® Connection Code Data Sheet for available options.)

The LiMAR® Helical Driver — Precision-engineered to deliver rotation exactly where and when you need it.

To find out more about how the Helical Driver can transform your Coiled Tubing operations, visit the product page or contact the LiMAR® team directly.