THE NEW im-PRES Sub®

7th July 2016

At LiMAR we have a strong record of refining tools to bring them into the modern age. We have pioneered new, innovative pulling tools, greatly enhanced power-type jars and relentlessly focused on improving the overall hands-on experience of working with downhole wireline tools.

Safety was the main focus when LiMAR designed the new im-PRES Sub®, but like all of our refined tools, cost effectiveness and operational flexibility were of equal priority.

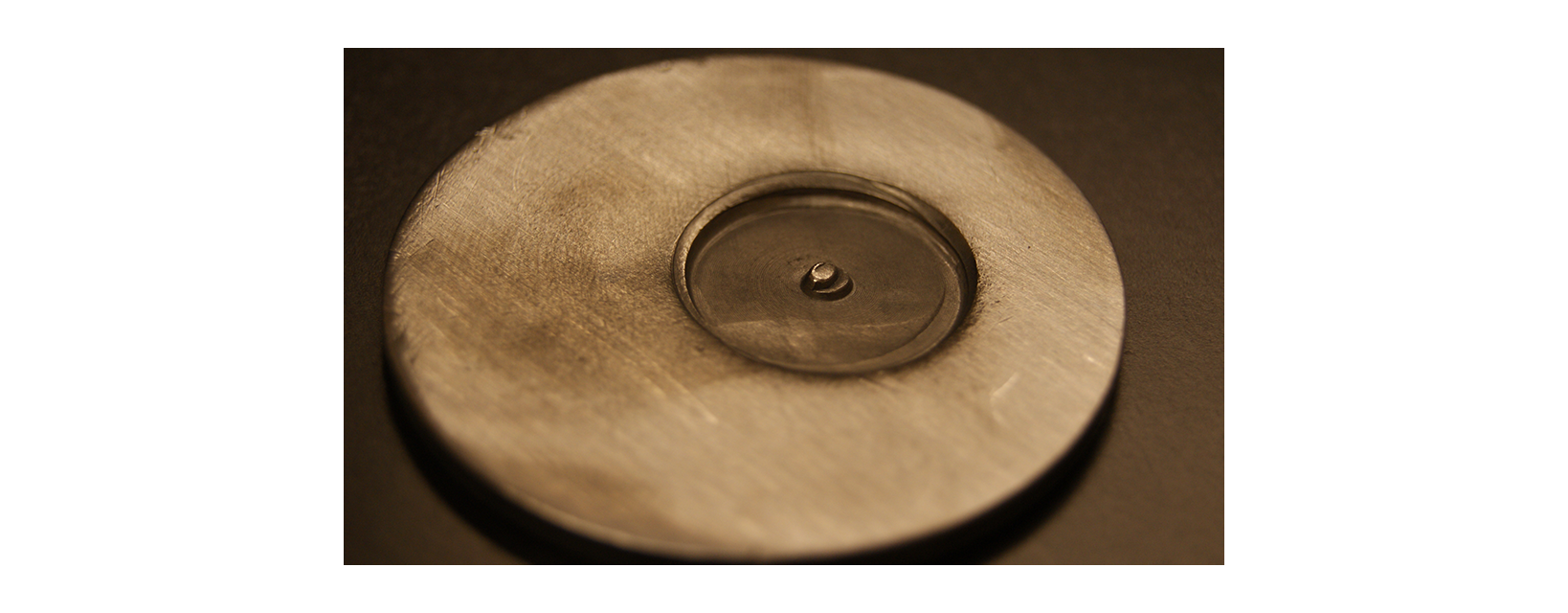

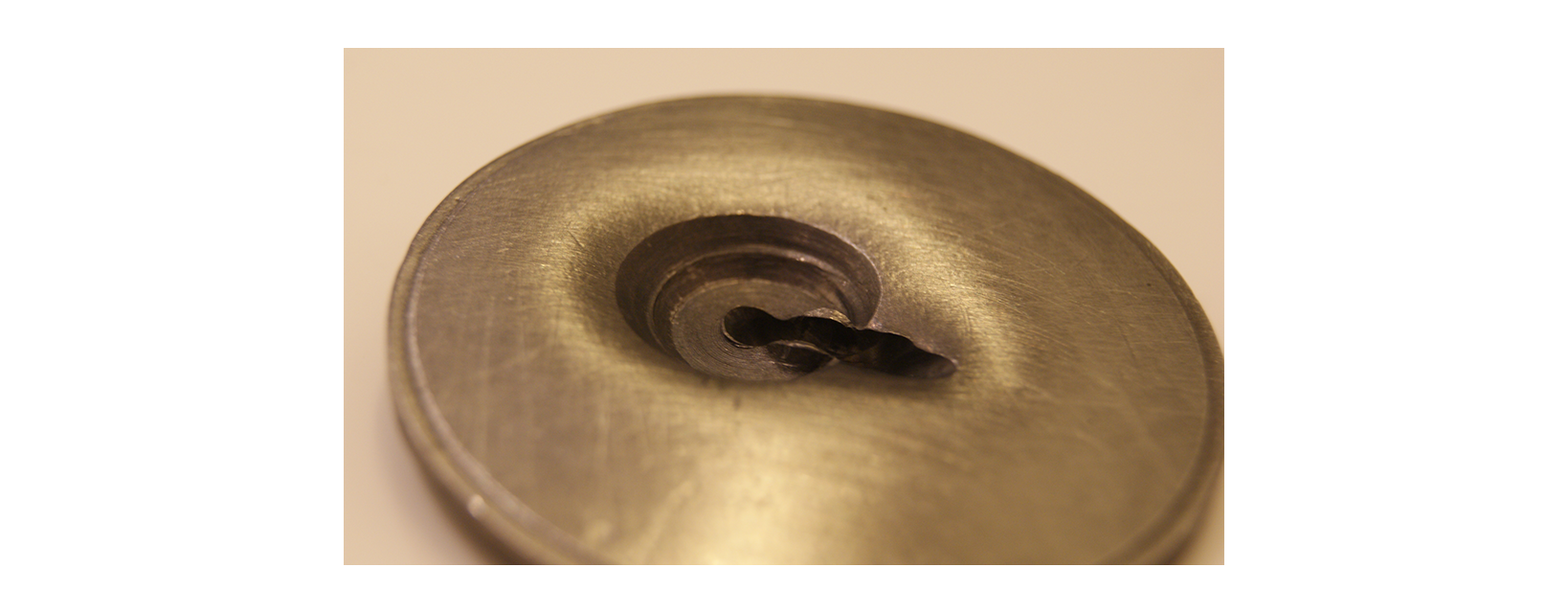

A Lead Impression Block (LIB) is a critical component, found in all slickline tool packages. Due to the melting, pouring and turning processes involved in the production or re-leading of an LIB, there are some serious health risks associated in working with a heavy metal. LiMAR have developed the im-PRES Sub® as a new industry alternative for obtaining a High Definition impression which also ensures these associated health risks are removed. Housed in a split skirt in any requested diameter, the unique, replaceable lead insert can be re-assembled with a fresh insert within seconds. With no on-site servicing or re-working required, there is no harmful exposure to lead filings.

The im-PRES Sub® allows for a quick turn-around of the same sub between wireline runs and due to the compact, lightweight design; 50% to 75% lighter than standard LIB’s, the im-PRES Sub® can be shipped inexpensively, handled safely and stored more efficiently. This offers stand-out technical advantages and cost savings as well as major health, safety & environmental benefits.

After the impression has been captured, the slim, lightweight insert can be kept as a permanent record for future reference / diagnostics.

For more information on the design features and benefits, please contact our sales team.