GETTING A GRIP WITH OPERATIONAL NEEDS

6th November 2015

THE BACKGROUND

When an Engineer creates a Coil intervention program, there’s a general understanding that the minimum I.D., within a completion’s design, will dictate the size criteria of the CT String and BHA selected for the pending operation. Good contingency planning will take into consideration any risks of unplanned events occurring, such as the CT Pipe parting or a BHA being left down hole. Further planning will consider the OD size criteria of any associated recovery (Fishing) tools that would be potentially needed; in order to operationally tackle the situation and successfully recover the Fish. Therefore, when planning contingencies (ideally and whenever possible), recovery tools such as standard Flo Release, Continuous & Cutting Overshots’ must be able to pass through a minimum restriction of a completion’s design. If they cannot pass, recovery efforts will be severely hampered.

What may be surprising to learn, is that on many occasions work is planned and carried out without contingency event planning. Should a recovery be required, it is soon discovered that a restrictive ID prohibits the use of a standard OD Fishing tool, which is needed to latch and recover the fish back to surface.

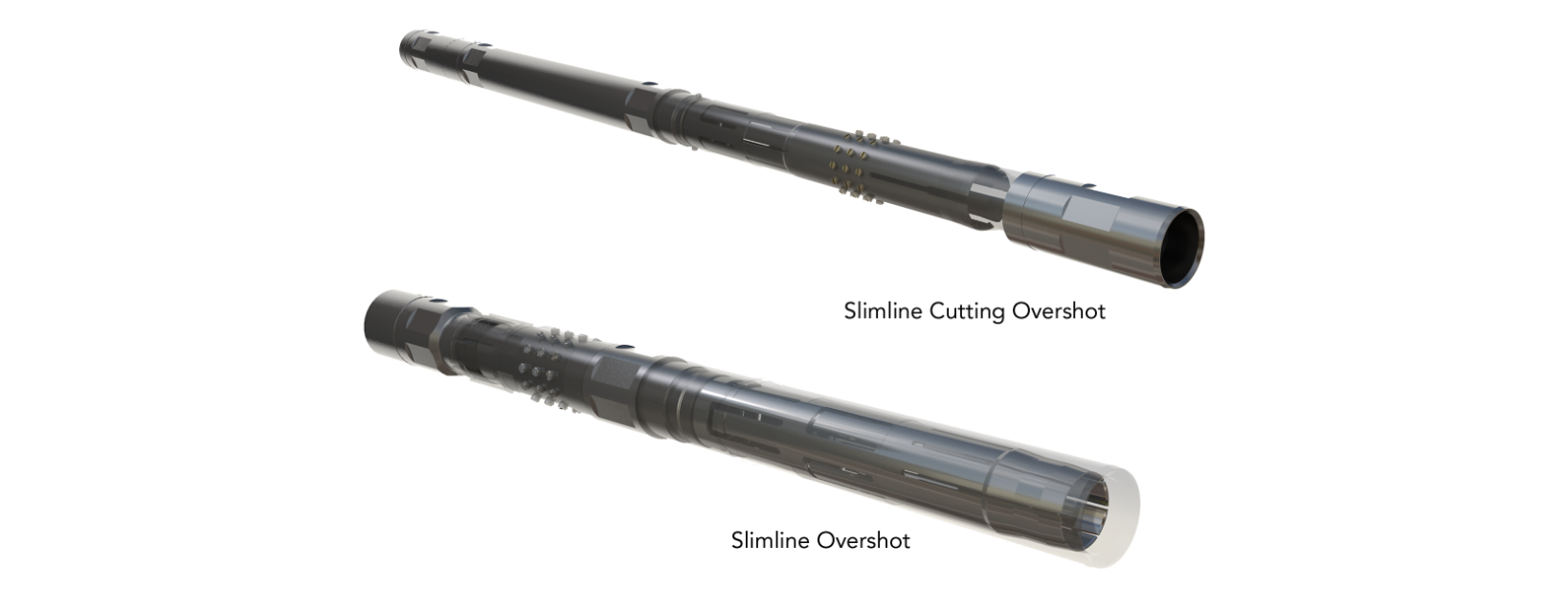

LiMAR has therefore dedicated a considerable amount of resources to develop and offer a ‘Slimline’ range of Overshots’; Continuous & Cutting Overshots’ to address issues of Pipe recovery operations . Providing an optimised range of Slimline Overshot’s’ to the market provides Coil intervention planners the choice of selecting larger CT string and BHA sizes, knowing that they can still be recovered, via a restriction, using LiMAR’s recovery tools. This option was previously limited by the existing OD’s of CT Overshot products available on the market.

THE BRIEF

- Reduce & minimise the O.D. of the existing CT Overshots’ - to enable them to pass through common restriction ID’s

- Maximise the Overshots’ “catch” range

- Design the Overshot to a strength that exceeds a typical CT string weight - by a minimum of 10,000 lbs

- Ensure that a standard or oversized housing can easily be fitted to the Slimline Tool - therefore reducing customers inventory & provide the option to utilise the Overshot in wells where well-bore restrictions are not an issue

- Provide a Cutting Overshot with a capacity to shear 110 grade material CT - at less than 40% of CT yield strength

- Build in a release mechanism to the Continuous Overshot

- Design with as many interchangeable parts, between the Cutting Overshot & the Slimline Overshot, as possible

THE OUTCOME

Once the desired specifications were achieved, the tools were exposed to rigorous in house testing; testing the tools performance against the heaviest wall thicknesses and highest grades of CT material that could be theoretically encountered operationally. The outcome has been the development of a Slimline Cutting Overshot capable of cutting and retrieving the technically advanced CT strings used in today’s challenging operating environments, and a Slimline Continuous Overshot featuring a shear release mechanism, which has not previously been available until now on such a Slimline product.

Both products are now commercially available in a range of sizes; please contact us for further information.