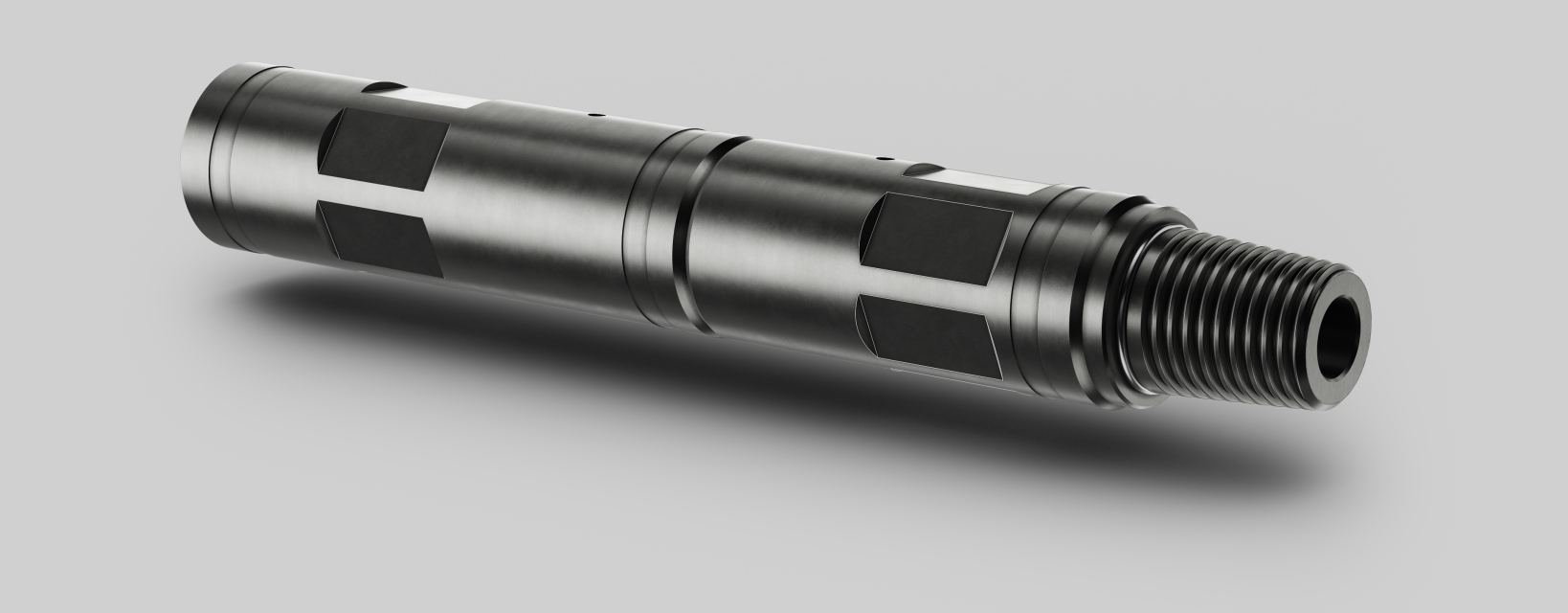

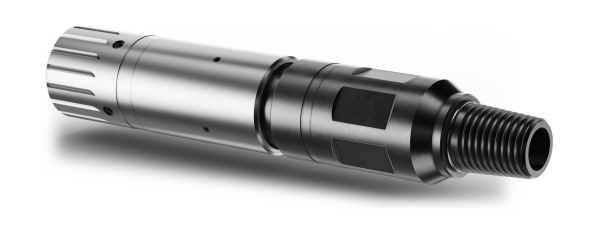

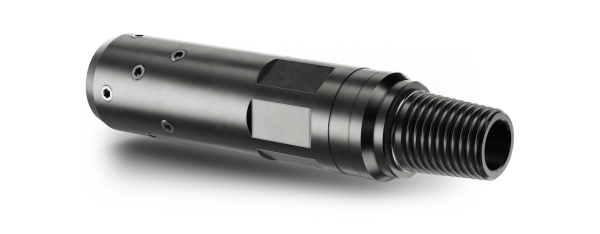

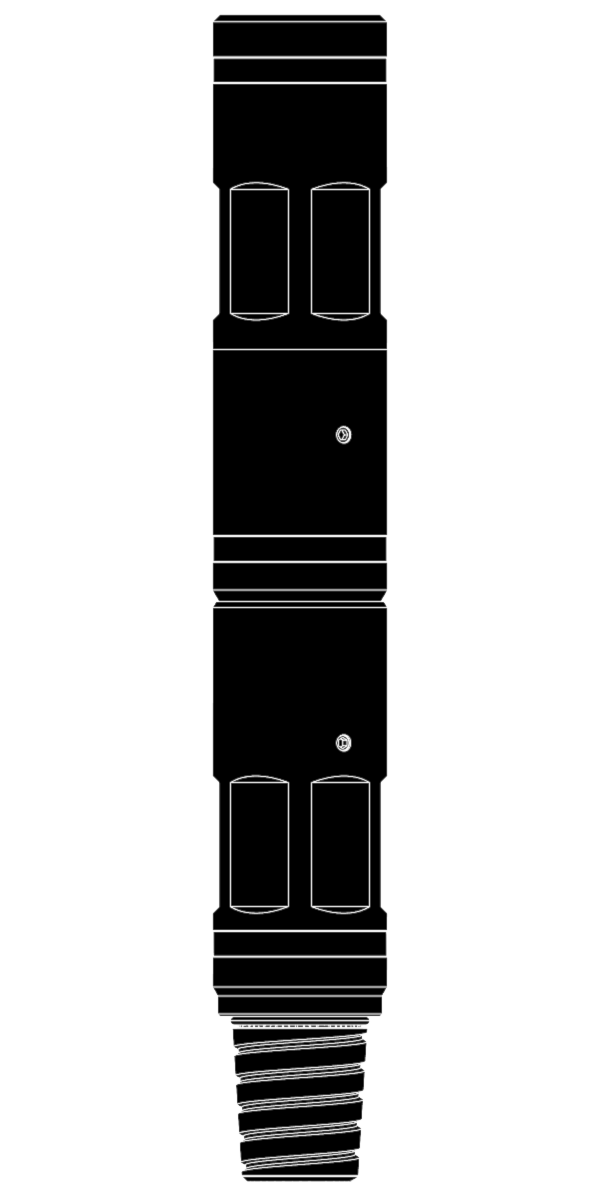

The LiMAR Torque-Thru Knuckle Joint is designed to provide a point of flexibility within a Coiled Tubing Bottom Hole Assembly (BHA) whilst maintaining a torque thru capability.

Configuring a Torque-Thru Knuckle Joint within the BHA enables it to pass unrestricted over nipple shoulders, tubing crossovers and other points where a rigid BHA may encounter difficulty. An internal hexagonal profile prevents the ball joint from rotating within the socket therefore providing the torque-thru capability required for use in conjunction with down hole motors, etc.

TOOL APPLICATIONS:

- To provide a point of flexibility within a Coiled Tubing BHA whilst maintaining a torque-thru capability.

DESIGN FEATURES & BENEFITS:

- Large thru bore

- Torque-thru ball joint

- Available in a range of sizes to suit industry standard BHA’s

- 10 degree deflection angle from centre line

- Connection options to suit customer requirements

- Simple, robust design ensuring ease of operation for the end user

- Selected components QPQ treated

- Hexagonal flats for safe make-up & break-out

- Corrosion resistant materials

TECHNICAL DATA

| Assembly Part No. | Actual OD | Maximum ID | Make up Length |

| 104-1500-XXX-RX | 1.500" | 0.500" | 10.45" |

| 104-1687-XXX-RX | 1.687" | 0.656" | 11.00" |

| 104-1750-XXX-RX | 1.750" | 0.656" | 11.00" |

| 104-2125-XXX-RX | 2.125" | 0.787" | 12.13" |

| 104-2250-XXX-RX | 2.250" | 0.787" | 12.13" |

| 104-2375-XXX-RX | 2.375" | 0.875" | 13.38" |

| 104-2875-XXX-RX | 2.875" | 1.187" | 14.82" |

| 104-3125-XXX-RX | 3.125" | 1.187" | 14.90" |

XXX - Last 3 digits of part number denotes connection type - Please refer to the connection code data sheet. For additional sizes or further information please contact sales