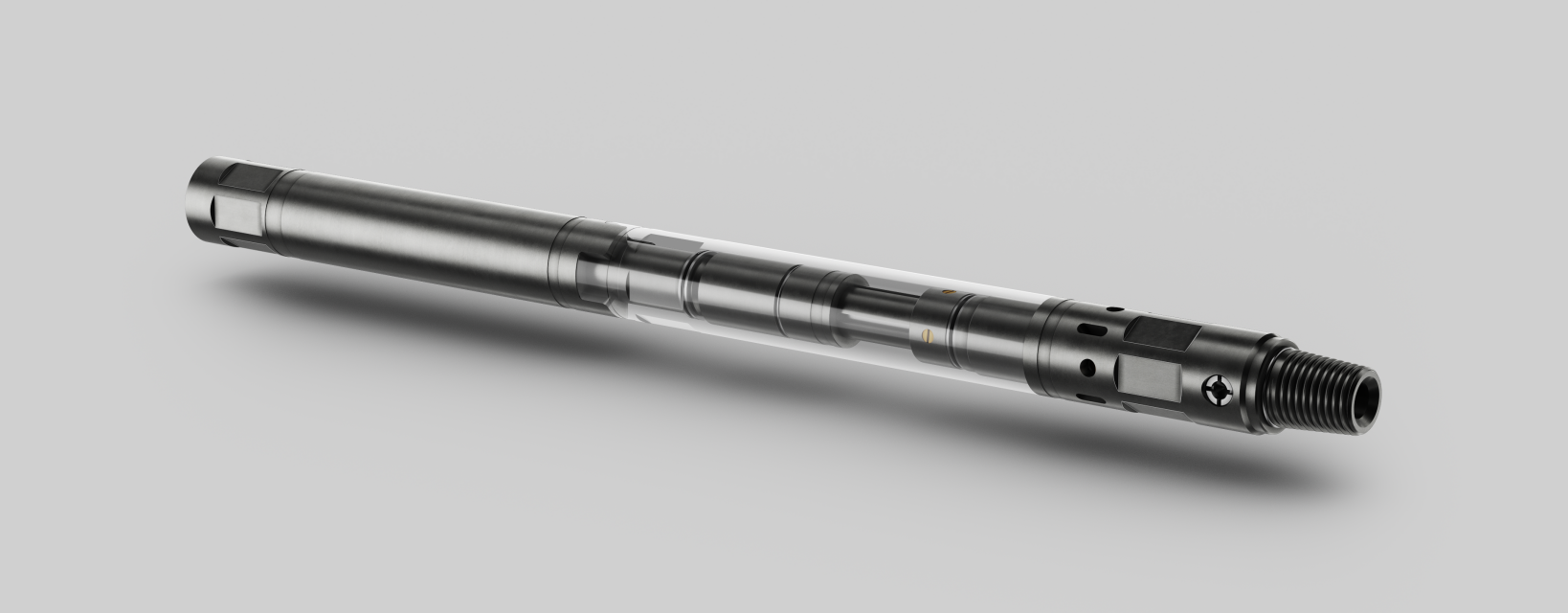

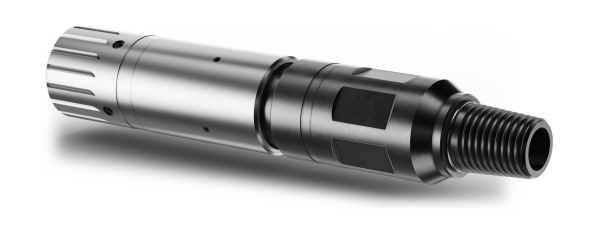

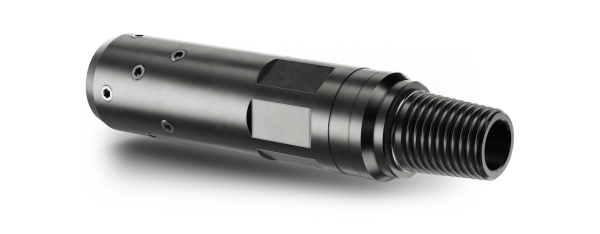

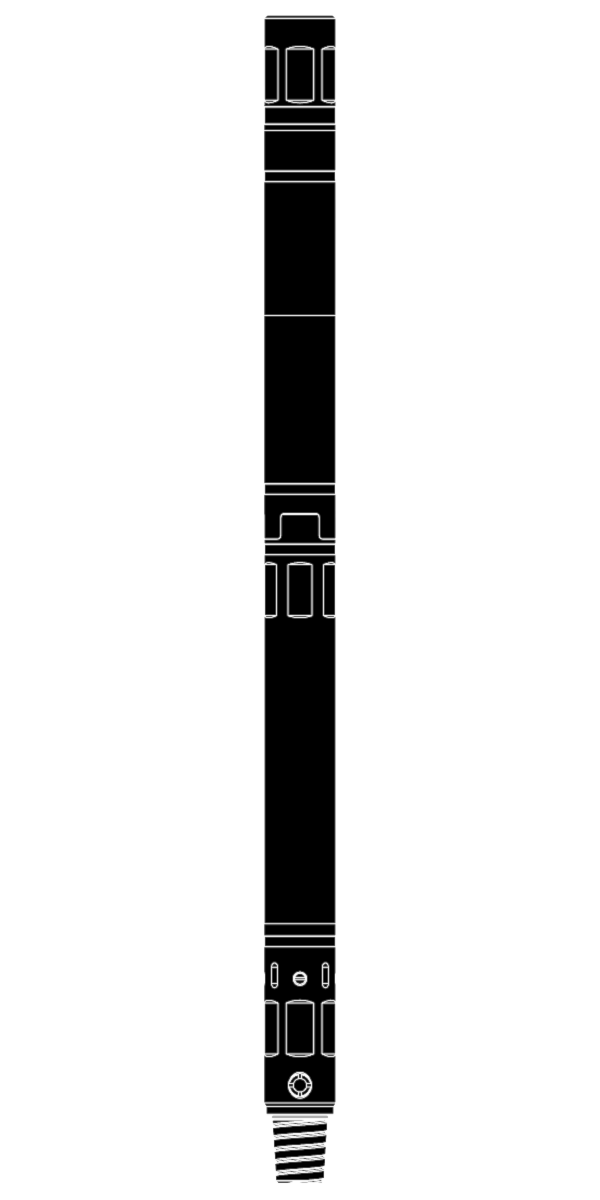

The LiMAR High Pressure Motorhead Assembly (MHA) is an evolution of the LiMAR MHA, designed to operate in the harshest of environments to a working pressure of 15,000 psi.

The MHA houses LiMAR Single Piece Double Flapper Check Valves, Hydraulic Disconnect and a Dual Circulation Sub in one combined unit. The user has the option of dressing the tool to permit circulation after dropping the ball but prior to disconnecting, a valuable feature in circumstances where the Coiled Tubing is stuck above the BHA.

TOOL APPLICATIONS:

- For use in the BHA directly below the CT connector

- To provide a double barrier from well pressure & contents

- Torque-thru hydraulic disconnect option for contingent release

- Integral dual circulating function for coil-to-tubing circulation

- For use in height restricted rig-ups

- Specifically designed for high pressure applications

OPERATIONAL APPLICATIONS:

- Fishing operations in conjunction with high impulse jars and impact hammers

- Milling operations in conjunction with hi-torque PDM motors

- Explosive perforating operations

- Abrasive perforating operations with availability of especially hardened MHA internals

- Packer setting operations in conjunction with Inflatable, Hydraulic & Explosive setting tools

- Acidising, Cementing & Stimulation operations

- High Temp / High Pressure operations

DESIGN FEATURES & BENEFITS:

- Single piece cartridge type Double Flapper Check Valve safety system

- Superior torque rating

- High tensile and compressive strength rating

- Proprietary High Pressure Tool Joint

- Optional flow paths during disconnecting

- 15,000 psi Safe Working Pressure

- Drop Ball operated release and circulating feature with maximised flo area

- Benoil type rupture disc fitted as standard

- Disconnect Sub fitted with LiMAR GS type internal fish neck profile

- Selected components QPQ treated

- Hexagonal flats for safe make-up & break-out

- Connection options to suit customer requirements

- Corrosion resistant materials

TECHNICAL DATA

| Assembly Part No. | Actual OD | Maximum ID | Disconnect GS Profile | Make up Length |

| 230-1687-XXX-RX | 1.687" | 0.375" | 1-1/2" GS | 26.18" |

| 230-2125-XXX-RX | 2.125" | 0.500" | 2" GS | 29.34" |

| 230-2875-XXX-RX | 2.875" | 0.937" | 3" GS | 35.35" |

XXX - Last 3 digits of part number denotes connection type - Please refer to the connection code data sheet.

For additional sizes or further information please contact sales