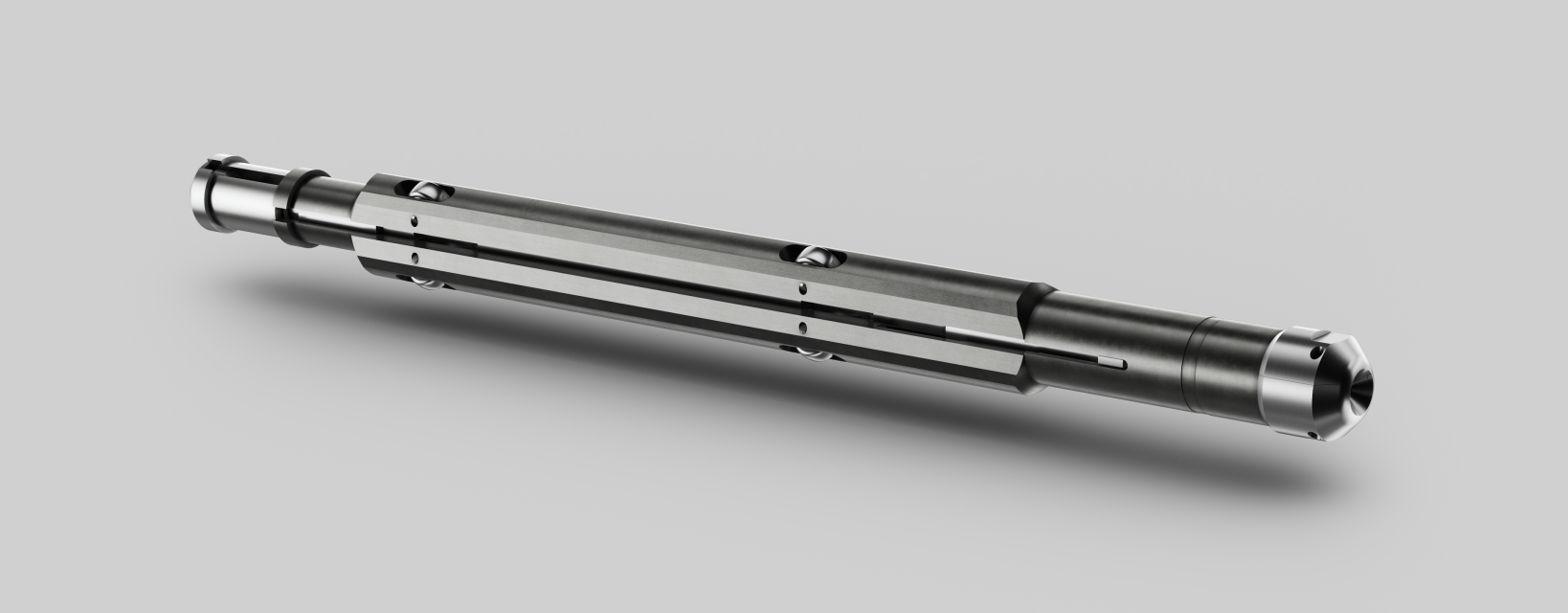

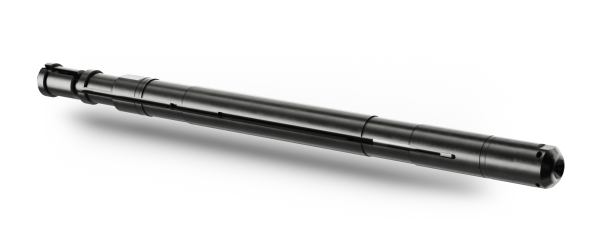

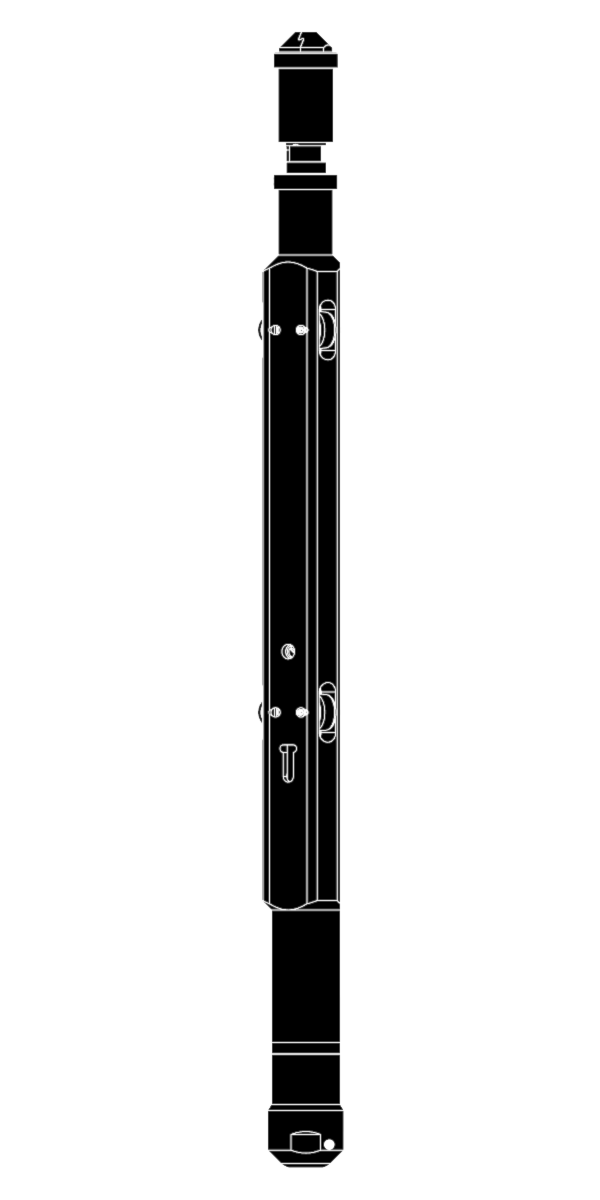

The LiMAR Rollerised Rotary Cutter is designed to drop, cut and clamp onto the wireline when a toolstring becomes inadvertently stuck down hole.

Utilising the fundamentals of the industry proven rotating knife technology, the Rollerised Rotary Cutter has been positively refined to further improve performance. The LiMAR® Cutter reduces exposure time around the wireline valve during assembly, increases the likelihood of reaching target depth using integral rollers along with further enhancements on the cutting technology to cleanly and more effectively sever the stuck wireline. The integral roller diameter has been specifically optimised so it is large enough to be deployed in various completions so as not to pass the toolstring to be fished.

TOOL APPLICATIONS:

- For cutting wire at the top of a stuck toolstring in deviated wells

DESIGN FEATURES & BENEFITS:

- Suitable for multiple line sizes

- Optimised diameter to prevent Cutter passing toolstring

- Premature-cut prevention feature

- Linearly supported rotary cutting mechanism

- Integral Rollers ideal for use in high angle wells

- Minimal connections during assembly over the wireline valve reducing exposure time under the lubricator and around a live well

- Simplistic, ergonomic design for rapid redress

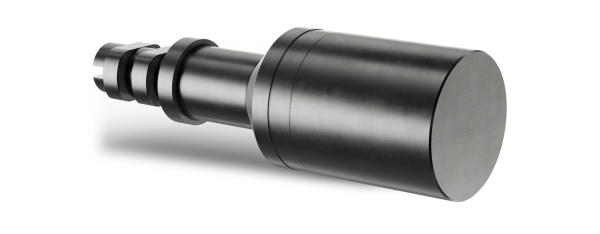

- Rollerised Go-Devil available to mimic Rollerised Rotary Cutter geometry to improve deployment trajectory

- Simple, robust design ensuring ease of operation for the end user

- Selected components QPQ treated

- Hexagonal flats for safe make-up & break-out

TECHNICAL DATA

| Assembly Part No. | Tubing Deployment Range * | Effective Roller OD | Fish Neck | Cutting Range | Deployment Length |

| 1150-1500-2150-RX | 2-7/8” / 3-1/2” | 2.150” | 1.375” | up to 0.218” | 27.36” |

| 1150-1875-2600-RX | 3-1/2" / 4-1/2" | 2.600" | 1.750" | up to 0.281" | 29.85" |

| 1150-2500-3500-RX | 5-1/2" / 7" | 3.500" | 2.313" | up to 0.312" | 36.08" |

For additional sizes or further information please contact sales

* Before deploying the cutter, the diameter of the stuck rope socket and the ID of the tubing should be considered in order to prevent the risk of the cutter nose passing down and to the side of the stuck fish.